Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: roll forming machine | Place of Origin: China |

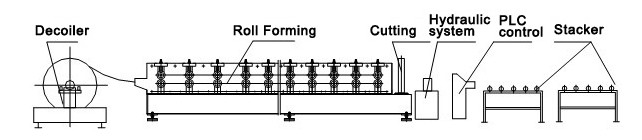

1. Description Of Omega profile metal drywall profile steel channel roll forming machine

Our Omega Profile stud and track roll forming machine consist of :

3tons single arm decoiler--Guideing device-Main forming system-Auto Non-stop cutting system--Control cabinet.

Our advanges:

1)Good and Stable quality

2) Strong bearing capacity

3)Non-deforming, fadeless

4)packing in carton

5)easily to install

1.Paintbrush

2.Durable and handsome

3.Moisture-resistant

4.Corrosion protection

Hot Dipped Galvanized Steel and Aluminum Alloy

Elegant

Rust proof

Fade proof

Acid & alkali resistant

Convenient for installation

Different dimensions can be made as required.

Main structure adopt independent hard column structure by 30mm thickness but not wall panel welded, with is with higher precision.

Forming rollers adopt high grade Cr12 but not GCR15 and 45# which gain more higher quality

2. Technical Details Of Metal Stud And Track Roll Forming Machine(CU/Omega or L type)

|

Suitable Raw Material |

|

|

Material |

GI GL Aluminum |

|

Thickness |

0.4-0.6mm |

|

Yield Strength |

235Mpa or 550MPA |

|

Main Technical Parameters |

|

|

Quantity of forming rollers stations |

10-12 steps |

|

Diameter of forming rollers shafts |

50mm full solid |

|

Roll Forming Speed |

45m/min without punching |

|

Forming rollers material |

Cr12 with heat treatment |

|

Cutter material |

Cr12MOV, with quenched treatment |

|

Controlling system |

INVETER |

|

Electric Power requirement |

Main motor power: 5.5kw |

|

Hydraulic unit motor power: 4kw Servo motor 1.5kw |

|

|

Electric voltage |

According to customer’s requirement We can do 208/220/380/415/440V etc please tell me your required voltage. |

|

Machine Specifications |

|

|

Weight |

About 2.8tons |

|

Size |

About 4.9M x 0.7Mx1.2M(length x width x height) |

|

Color |

Main color: Grey or as your requirements |

|

Warning color: yellow |

|

3. Main Components Of Metal Stud And Track Roll Forming Machine

|

Manual Decoiler-3tons |

1 Set |

|

Guiding device |

1 Set |

|

Main Roll Forming Unit |

1 Set |

|

Post Cutting Unit--Non-stop |

1 Set |

|

Hydraulic Station |

1 Set |

|

PLC Control System |

1 Set |

|

Reveiving Table-2m |

1 Set |

4. Production Flows Of Metal Stud And Track Roll Forming Machine

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages Of Our Metal Stud And Track Roll Forming Machine

· More than 10 engineers and More than 10 designers with more than 10 years experience

· We have completed production system. And more than 20 sets of CNC machines which can support lots of machine.

· Our machine's warranty period is 12 months and and we supply the technical support for the whole life of the equipment.

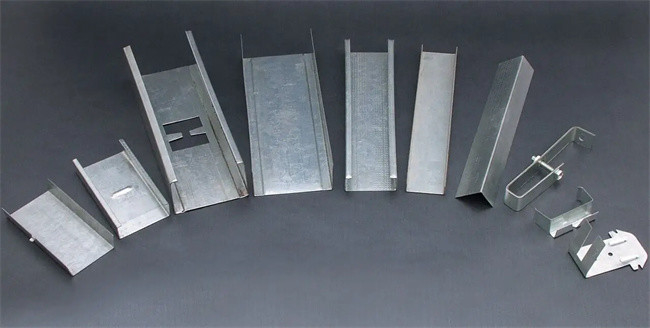

6. Application Of The Metal Stud And Track Roll Forming Machine

This machine is widely used in the production of the metal roof sheets and wall panel. our machines are exported to many countries: Rwanda, Thailand, Philippines, Dubai, USA, South Africa, Peru, Russia, Saudi Arabia, Malaysia, Indonesia, etc.

7. Product photos Our Metal Stud And Track Roll Forming Machine

8. FAQ

Q: How to visit our company:

A: 1.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3. Fly to Guangzhou aiport: By air From Guangzhou to Beijing airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Q. How to get a quotation?

A: 1. Give me the profile drawing and the thickness of your material it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own profile drawing, we can recommend some models according to your local market standard.

Q. What's your payment terms and delivery time?

A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.

![]()